Beverage Manufacturers

America's Leading beverage manufacturing Company? We will help you to manufacture, market and sell your new drinks!

Beverage Manufacturers

America's Leading beverage manufacturing Company? We will help you to manufacture, market and sell your new drinks!

Are You Looking For A Beverage Manufacturer

We can fill any size can or bottle and can help you grow your new beverage business! Trusted by global beverage manufacturers for 25 years

quality, loyalty and value

〰️

quality, loyalty and value 〰️

Carbonated or Non-carbonated, Hot-Fill, Cold-Fill & just about any process, America’s most innovative beverage manufacturers. We will help you produce & market your drinks.

Better Business Bureau, the longest standing business review organization in America rates Power Brands an A+ beverage manufacturing company. Trust the BBB they have rated companies since 1912.

Tips from leading beverage manufacturers.

1. Make sure you have a production ready beverage formula. To guarantee smooth, scalable production, have a beverage scientist refine your recipe and source your ingredients. A production-ready formula stays true to your original concept but uses high-quality ingredients that are consistently available in mass quantities. Request free information >

-

1. Start with a clean base

Every drink begins with water, tea, juice, or another neutral liquid. This choice sets the stage for flavor, clarity, and texture. If the base isn’t right, nothing else will be.2. Give every ingredient a clear role

Don’t just throw things in. Sweeteners balance taste, acids sharpen flavor, colors attract the eye, and functional ingredients add health benefits. If an ingredient doesn’t serve a purpose, leave it out.3. Taste is non-negotiable

No matter how innovative, if it doesn’t taste good, it won’t sell. Never sacrifice flavor for novelty. The only exception is when function is the sole priority, like in certain medicinal drinks.4. Balance benefits with experience

Functional additives often bring bitterness or unwanted changes in color and texture. Always test and adjust — mask, balance, or scale back anything that gets in the way of taste and appeal.5. Test early, fix fast

Run small trials to check taste, mouthfeel, and appearance. Do stability checks to see how your drink holds up over time. Don’t wait until production to discover problems.6. Scale with consistency

The biggest test: can your formula move from the lab bench to large production runs without losing taste or quality? If not, fix it before it hits the market.Golden rules to remember:

If it tastes bad, drop or fix the problem ingredient.

If function and flavor fight, flavor usually wins.

If it can’t scale or stay stable, it’s not ready.

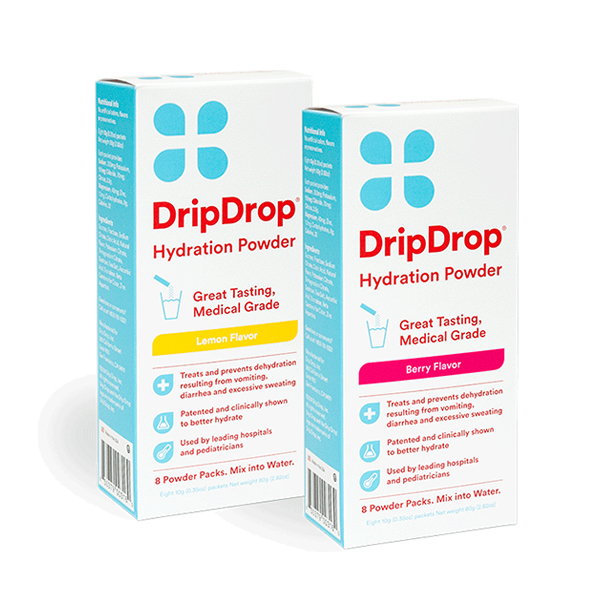

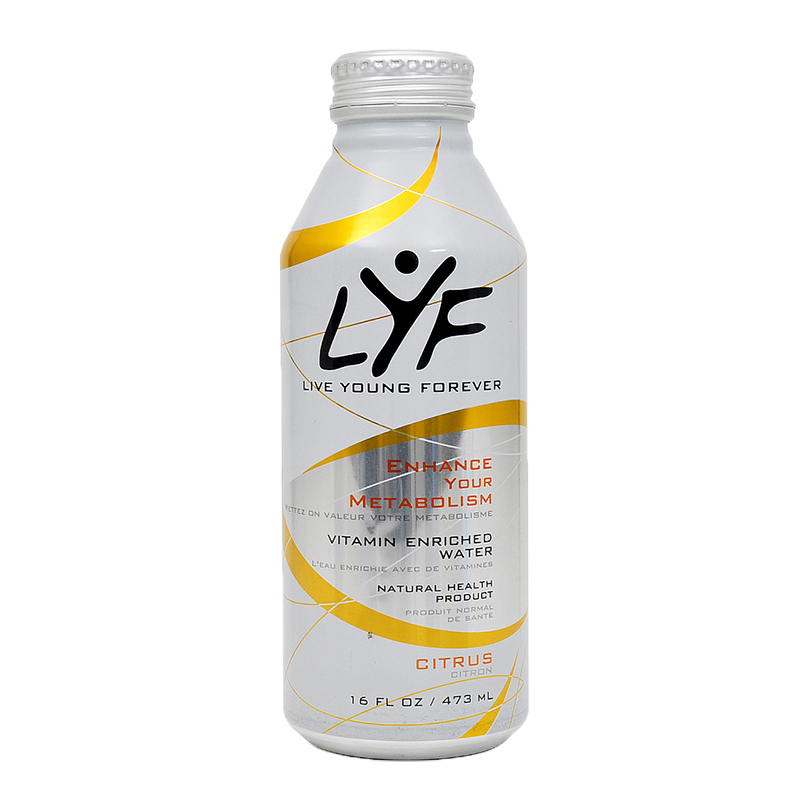

2. Choose the right kind of beverage packaging for your drink. Your decision on which type of packaging to use comes down to two main points a. What type of process is required to manufacture your beverages - this will determine the type of container used? b. The type of consumer you are targeting - this determines style & shape of container. Request free information >

-

1. Start with the process

How your beverage is made dictates your options.Carbonated drinks → cans or PET bottles (handle pressure well).

Juices & dairy → hot-fill or aseptic lines (best in glass, PET, or cartons).

Functional shots → usually small PET bottles or glass vials.

Your package must protect the drink and fit the filling line.

2. Know your consumer

Once the technical side is set, think about who’s buying:Energy drink fans → sleek cans.

Health-focused buyers → glass bottles or natural cartons.

Eco-minded shoppers → recyclable or paper-based packs.

Size matters too: single-serve for on-the-go, bigger bottles for value and sharing.

3. Find the balance

The winning package is both practical and appealing. If it doesn’t run on the line, it fails. If it doesn’t connect with your customer, it fails. The best choice always meets both needs.

3. Choose the right kind of label for your new beverage. Choosing the right beverage label is very important to the marketing & sales of a beverage brand. The look & feel of the product is crucial to its success but don't forget to keep an eye on cost.

-

1. Label matters

Your label is the first thing consumers see. It tells your story before they ever taste your drink.2. Match label to product type

Energy & lifestyle drinks → bold, eye-catching designs.

Health & wellness products → clean, natural, trustworthy look.

Premium beverages → elegant finishes, metallics, or textured materials.

3. Design with cost in mind

A stunning label is useless if it’s too expensive to scale. Always balance creativity with budget so the design works in real-world production.Bottom line: The right label makes your drink stand out, matches your consumer’s expectations, and fits your budget — all three must align.

4. Choosing the best closure for your new product is also important. You must consider if the consumer will want a wide or narrow opening to drink out of? Should the container be resealable? There is also the cap color & the shape to consider.

-

1. Function comes first

Decide how the consumer will use it:Wide openings → quick, heavy drinks like shakes.

Narrow openings → sippable, on-the-go beverages.

Resealable caps → convenience and multiple servings.

2. Don’t forget design

Cap color, shape, and finish should match your brand look. A bold cap can stand out on shelf just as much as the label.Bottom line: Pick a closure that makes the drink easy to enjoy, aligns with the product’s use, and visually reinforces the brand.

5. What type of box or tray will you use to pack your beverage for shipping to retailers? Will you use a box or a tray? If its a tray will you use shrink film and will the film be decorated? How many drinks should you put into each case?

-

1. Box or tray?

Boxes → more protection, good for shipping longer distances.

Trays → cheaper, lighter, often paired with shrink film for stability.

2. Shrink film options

Clear → keeps cost down, product visible.

Printed/decorated → adds branding and shelf appeal, but costs more.

3. Case count

Think about weight, handling, and retailer standards:12 or 24 packs are common.

Smaller counts work for premium products or heavy bottles.

Bottom line: Pick a pack style that protects the product, fits your retail channel, and balances cost with brand impact.

6. Where should your beverage manufacturer be located in relation to the market that you are going to supply? Is it better to produce closer to where you market or to get smaller production runs done at locations that aren't as conveniently located.

-

1. Close to your market

Lower shipping costs

Faster delivery times

Easier oversight and quality control

2. Further away

Sometimes allows smaller production runs

Access to specialized equipment or capabilities

May work for test markets or limited launches

Bottom line: Producing near your target market usually saves money and time, but niche products or small runs might justify working with a plant that’s farther away. Balance cost, speed, and flexibility.

7. How many case should I produce when I first get started manufacturing beverages? Should I be worried about over producing or should I be more concerned about running out of drinks? Who should I ask about this very important decision?

-

1. Don’t overproduce

Big runs tie up cash and storage. If the product needs changes, you’re stuck with old inventory.2. Don’t run out too fast

Too little product can frustrate retailers and customers. Plan enough to support your launch window.3. Ask the right people

Lean on your manufacturer, distributor, and advisors. They know typical volumes for your channel and can guide a safe starting point.Bottom line: Start smaller, test the market, and scale up once you see real demand. Running out briefly is better than being buried in unsellable stock.

8. Once my drinks have been produced where do I store them & how do I move them around cost effectively & safely? How do I get hold of companies that can store my products for me and then help me to to ship them everywhere?

-

1. Storage

Finished drinks need to be kept in a secure, climate-controlled warehouse. This protects shelf life and keeps products safe until they’re shipped.2. Distribution

Partner with logistics providers (3PLs) that can both store and ship your cases. They’ll move products to retailers, distributors, or even direct-to-consumer at scale.3. Cost & efficiency

The most cost-effective setup is often regional warehouses near your target markets, reducing freight costs and delivery times.Bottom line: Don’t try to handle storage and shipping yourself. Use a professional warehousing and logistics company that knows beverages and can manage both sides — storage and delivery.

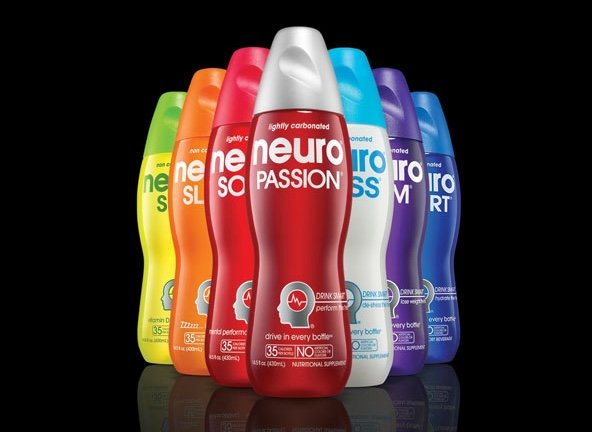

Produce Your Beverage with the Experts Behind the World’s Top Brands

At Power Brands, we don’t just make beverages - we create beverage success stories. From concept to shelf, we ensure your product is produced to the highest standards and ready to compete in today’s market.

Why Choose Power Brands for Beverage Production?

Proven Expertise – Trusted by some of the world’s leading beverage brands to deliver top-quality drinks.

Flexible Production – Small-batch or high-volume production, maximum quality, efficiency, and profit.

Global Network of Beverage Manufacturers – Thousands of trusted manufacturers and suppliers at our fingertips.

End-to-End Support – From beverage formulation and production planning to packaging and logistics.

Ready for Market Success – Our team works alongside you to ensure your drink is produced on time and on budget.

It’s time to bring your vision to life.

Get your beverage into production — and into the hands of your customers.

A brief history of the beverage manufacturing industry!

The Beverage Manufacturing Journey

If you’re new to the beverage industry and exploring the drink manufacturing process, understanding its history will help you see just how far it has evolved.

A Global Industry of Precision and Scale

The beverage manufacturing process is one of the most efficient manufacturing systems in the world.

Driven by enormous global demand, American, European, and Asian drink manufacturers have become increasingly equipped to manufacture drinks at high speed and low cost.

As a beverage manufacturer in these regions, you are connected to some of the largest and most competitive beverage markets on the planet.

From Ancient Roots to Large-Scale Production

The origins of beverage manufacturing date back to the dawn of civilization. For as long as history has been recorded, we have been beverage manufacturers - brewing tea, growing grapes for wine, and creating small-batch drinks in home industries.

These early drink manufacturers often made slightly more than they needed, selling the surplus to supplement their income. Over the centuries, the process became more streamlined, with beverage manufacturing shifting to a much larger scale:

Farms producing grapes for wine pressing

Tea plantations with processing facilities

Other forms of large-scale drink manufacturing emerging

By this stage, a single beverage manufacturer could produce enough product to supply an entire region.

Pioneers of Modern Beverage Manufacturing

Fast forward to the late 19th century - Coca-Cola, founded in 1886, became one of the first major international beverage manufacturers. This marked the beginning of the modern era, setting the stage for today’s highly advanced drink manufacturing and beverage production industry.

Discover more about this dynamic, ever-expanding business.

Request Free Information ›

Over the last 60 years there have been a lot of important milestones in the beverage manufacturing industry.

- In 1966 Gatorade was born, it became the worlds first popular sports drink. Drink manufacturing would never be the same.

- In 1971 Starbucks emerged and Seattle would become another turning point for the drink industry.

- In 1972 a couple of natural food store owners wondered if a healthy drink industry would be possible? The answer was yes and Snapple was created, it has kept drink manufacturers busy for over 35 years.

- 1978 Although there was plenty of fresh water flowing through the taps in America - Perrier and Evian became the first widely available bottled waters.

- In 1980 the only way to get fresh juice was to squeeze it yourself. Odwalla one of the leading innovators in the drink industry would change that for the better.

- It was 1981 when Red Bull energy drink began its iconic rise, setting the stage to become one of the most successful and influential drink manufacturers in history, reshaping the beverage industry forever.

- In 1982 Diet Coke became the nation's favorite diet soda.

- In 1992 Pepsi-Cola revolutionized drink distribution by including Lipton and Ocean Spray as part of its drink distribution strategy.

- In 1995 Pepsi introduced Aquafina and Coca-Cola introduced Dasani, bottled water one of the largest segments of the drink industry was here to stay.

- In 1996 SoBe defined the functional drink category.

- 2007 Coca-Cola buys Vitamin Water for a record 4.1 billion dollars and the drink industry keeps growing.

- 2014 Coca-Cola and Monster Beverage announce that Coke will make a net cash payment of $2.15 billion in exchange for a 16.7% stake in Monster Energy Drink.

- 2016 Dr Pepper Snapple Group Inc. announces that it would be buying Bai Brands, maker of antioxidant and other health-oriented beverages, for $1.7 billion.

-2016 PepsiCo agreed to fully acquire sparkling probiotic drink maker KeVita, a deal that will diversify the soda and snacking gia nt's portfolio by adding another brand that taps consumer interest in healthier beverages

-2018 Keurig Green Mountain acquired Dr Pepper Snapple Group in a deal worth $18.7 billion, and the merged company changed its name to Keurig Dr Pepper, creating the third largest beverage company in North America. On July 10th, shares in Keurig Dr Pepper (KDP) began trading on the New York Stock Exchange.

-2020 The Coca‑Cola Company Acquires Remaining Stake in fairlife LLC. Headquarters in Atlanta, Georgia., and distributed in Canada, China and the United States by The Coca-Cola Company. fairlife is a deliciously creamy and full flavored fairlife Whole Ultra-Filtered Milk has 50% less sugar and 50% more protein than regular milk.

-2020 Pepsi announced the acquisition of Rockstar Energy Drink for US$3.86 billion adding to its portfolio of energy drinks that includes Mountain Dew energy drinks. Pepsi has around 5% of the energy drink market in the US.

-2021 The Coca-Cola Company announced that it has acquired full ownership of BODYARMOR, a line of sports performance and hydration beverages. Coca-Cola initially acquired a 15% stake in BODYARMOR and is paying $5.6 billion in cash for the remaining 85% of the company.

- 2021 PepsiCo sold Tropicana, Naked and other North American juice brands to private equity firm PAI Partners in a $3.3 billion deal. PAI will have the irrevocable option to purchase some of PepsiCo’s European juice businesses.

- 2024 Ghost Energy Drink is Acquired by Keurig Dr Pepper for $990 million for 60% stake with plans to purchase the remaining 40% in 2028. Ghost Energy was first produced by Power Brands in Los Angeles.

- 2025 - Keurig Dr Pepper Acquires Peet’s Coffee for ~$18 Billion, Then Announces Company Split into separate Coffee (Keurig & Peet’s) and Soft-Drink Businesses (Dr Pepper, Snapple, 7UP, and Canada Dry, energy drinks & other categories.

Coca-Cola is still the largest soft drink manufacturer in the world.

While many different categories make up the American beverage product picture, carbonated soft drinks (CSDs) and their diet counterparts continue to be some of the most popular, hence the extensive network of soft drink manufacturers. Since the early days of our nation’s history, carbonated soft drinks have occupied a unique place in the hearts, minds and palates of the American consumer and this was all made possible by our nations soft drink manufacturers.

The term soft drink is derived from the phrase “soda water,” dating back to 1798. At that time, soft drink creation and soda fountain manufacturing were handled by local pharmacists because of their experience with chemistry and medicine. In 1835, the first bottled soda water was produced. This marked the start of carbonated soft drink manufacturing.

As the local drugstore evolved into the central attraction in most American towns and neighborhoods, the pharmacist was integral in providing beverages that were part pharmacology and part refreshment. Soft drink manufacturing was part art and part science back then. By 1876, root beer entered the marketplace, but it wasn’t until five years later that the first cola-flavored beverage was unveiled. Soft drink manufacturers were about to become very busy. It would be more than 70 years before the first “official” diet soft drink was introduced in 1952, this marked a significant change for the soft drink manufacturing industry. In 1958, RC Cola introduced Diet Rite®, the first nationally distributed diet soft drink. Tab, Fresca® and Diet Pepsi® entered the marketplace in the 1960s;

Sugar-free 7UP was introduced in 1970; & Diet Coke made its debut in 1982.

Soft drink manufacturers were in full stride by this point.

In 2024, the U.S. soft drinks market was valued at approximately $286.25 billion and is projected to grow at a compound annual growth rate (CAGR) of 7.7% from 2024 to 2033.

This growth is driven by increasing consumer demand for low-calorie, zero-sugar, and functional beverages enriched with vitamins and minerals. For information on starting your drink company contact America’s leading beverage industry experts.

Beverage Manufacturers

Beverage Manufacturers

Talk to a beverage manufacturing expert

Looking for beverage manufacturers make your idea into to an actual finished product?

Have a finished formula and trying to find a beverage manufacturing company to produce your drinks for you? Our beverage development and manufacturing exerts will analyze your concept and work with you to create the best possible formula, packaging and production process.

We will get you from start to store in 90 days.

When it comes to drink bottling nobody has more experience than Power Brands, we have helped bottle drinks for global drink companies as well as hundreds of small companies and startup from around the world. Talk to a drink bottling expert.