Trying to find the right company to produce your drinks?

We manufacture beverages in any size can or bottle, hot-fill, cold-fill, carbonated & non-carbonated alcoholic & non alcoholic drinks.

One Bottle or a Million We’ve Got Your Beverage Production Needs Covered!

OVER 25 YEARS OF PRODUCING DRINKS

Before you set up your first mass production run, let us help ensure that your beverage formulation is ready for manufacturing. Request Free Information >

We will help you to purchase all of the raw materials that will need your beverage production, we will make sure the correct quantity of ingredients and any other raw materials that you need are shipped to the manufacturer on time. We will make sure your beverage containers, caps, labels and cartons are all the correct specifications and arrive ready to be turned into your drink.

Power Brands will help you ship and store your new beverage after production. Our beverage production and logistics experts will guide you through quality control, shipping and warehousing your newly produced beverages. Working with a Power Brands beverage production expert will ensure that you have a less stressful and more successful experience. Request Free Information >

The Ultimate Beginner’s Guide to Beverage Production

Whether you’re a budding entrepreneur or a curious enthusiast, diving into the world of beverage production can be both exciting and challenging. In this comprehensive guide, we’ll walk you through the fundamentals of creating your own drinks—from concept to market launch. By understanding key processes and best practices, you’ll be better positioned to produce high-quality beverages that resonate with consumers. Let’s get started!

1. What Is Beverage Production?

Beverage production refers to the process of developing, manufacturing, and packaging drinks for commercial or personal use. It encompasses a range of activities—such as product formulation, ingredient sourcing, processing, quality control, and distribution—all aimed at delivering a safe, appealing, and market-ready product.

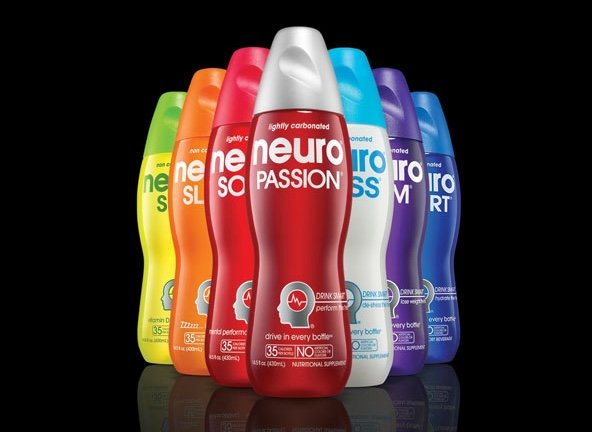

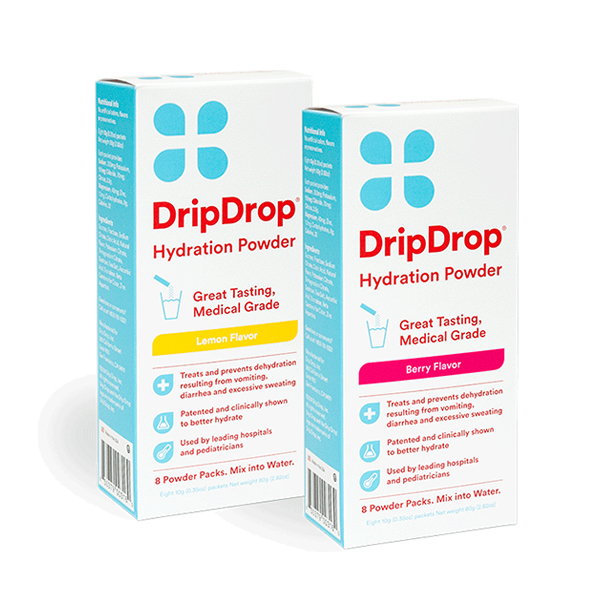

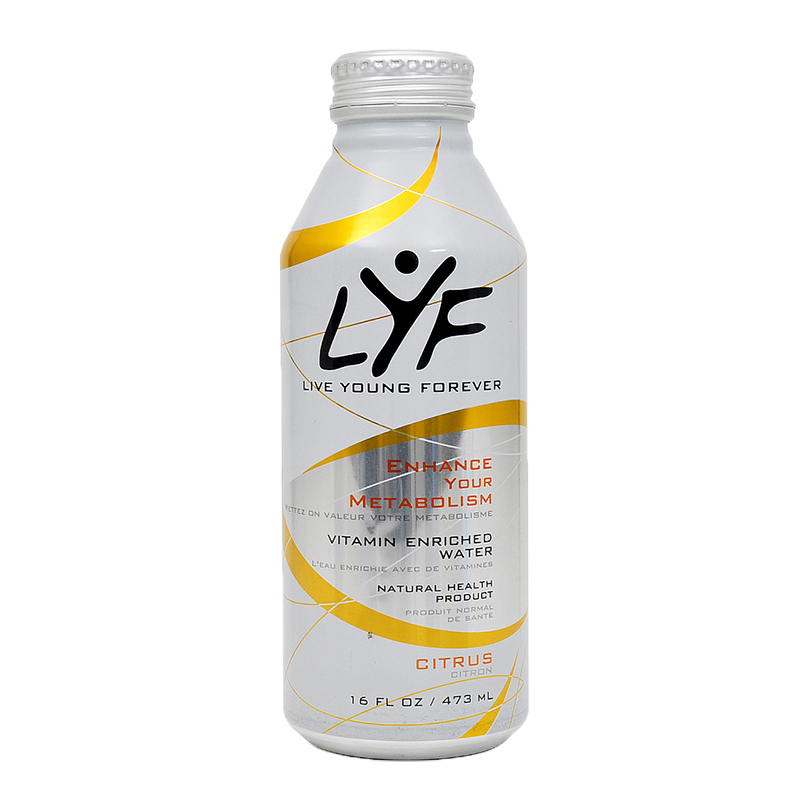

Some common beverage categories include:

• Soft Drinks (sodas, carbonated water, flavored drinks)

• Functional Beverages (energy drinks, sports drinks, health-focused juices)

• Alcoholic Beverages (beer, wine, spirits)

• Dairy-Based Drinks (milk, milkshakes, yogurt drinks)

• Plant-Based Beverages (almond milk, soy milk, coconut water)

• Tea and Coffee (ready-to-drink bottles, canned coffee, iced tea)

No matter the beverage type, beverage production involves a standardized set of steps to ensure consistency, quality, and compliance with regulations.

2. Conceptualizing Your Beverage

Before diving into the manufacturing process, it’s essential to outline your vision:

1. Market Research

• Identify gaps in the market, emerging trends, and consumer preferences.

• Study competing products and analyze pricing, packaging, and flavor profiles.

2. Unique Selling Proposition (USP)

• Determine what sets your beverage apart—organic ingredients, health benefits, or artisanal production methods.

3. Target Audience

• Define your core customers, whether they’re health enthusiasts, busy professionals, or flavor adventurers.

Starting with a clear concept helps you create a strategic roadmap for the rest of the beverage production journey, whether you're developing functional drinks, alcoholic beverages, or innovative wellness blends.

3. Beverage Formulation and Recipe Development

Once you have your concept, the next step in beverage production is developing a formula that balances taste, texture, and shelf life.

1. Ingredient Selection

• Source high-quality components to achieve the desired flavor.

• Consider sweeteners (sugar, stevia, honey), flavor additives (natural extracts, fruits, syrups), and preservatives.

2. Lab Testing and Prototyping

• Collaborate with food scientists or product developers to perfect your recipe.

• Conduct small-scale batches to adjust sweetness, acidity, and mouthfeel.

3. Stability and Shelf Life

• Determine storage conditions (ambient, refrigerated, or frozen).

• Test the product’s shelf stability under various temperatures and conditions.

Investing time and resources into research and development reduces costly errors during large-scale beverage production.

4. Sourcing Equipment and Ingredients

Choosing the right equipment is crucial for efficient beverage production. The size and complexity of your operation will influence your choices:

• Small-Scale Equipment: Ideal for small batches, often found in craft or artisanal beverage production setups.

• Industrial-Scale Machinery: Automated systems for large production runs (bottling lines, pasteurization systems, high-capacity mixers).

When sourcing ingredients, prioritize quality and consistency. Building relationships with reputable suppliers and negotiating favorable contracts can ensure a steady supply and cost-effective pricing.

5. Production Processes and Techniques

Beverage production often involves these essential steps:

1. Mixing and Blending

• Combine ingredients in controlled batches.

• Maintain consistent ratios to ensure flavor uniformity across all batches.

2. Filtration and Clarification

• Remove unwanted solids or impurities to improve clarity and mouthfeel.

• Techniques like centrifugation, carbon filtration, or microfiltration may be used.

3. Thermal Processing (Pasteurization)

• Destroy harmful bacteria and extend shelf life.

• Common methods include high-temperature short-time (HTST) or ultra-high temperature (UHT) processing.

4. Carbonation (If Applicable)

• Infuse carbon dioxide to create sparkling beverages.

• Monitor CO₂ levels carefully to achieve the right level of fizziness.

5. Packaging

• Fill and seal in bottles, cans, or other containers.

• Label and brand according to regulatory standards, including nutritional information and allergen warnings.

6. Quality Control and Compliance

Maintaining high standards of quality and adhering to regulations is paramount in beverage production.

1. Quality Control (QC) Testing

• Monitor pH levels, Brix (sugar content), and microbial counts.

• Conduct regular taste tests to ensure flavor consistency.

2. Good Manufacturing Practices (GMPs)

• Implement standardized procedures for hygiene, equipment maintenance, and employee safety.

• Train staff to follow protocols and document all processes meticulously.

3. Regulatory Approvals

• Obtain required licenses and permits, depending on your local or national regulations.

• Meet labeling requirements (e.g., ingredient lists, nutritional facts) set by agencies like the FDA (in the U.S.) or EFSA.

By establishing a robust quality control framework, you protect your brand’s reputation and maintain consumer trust throughout the beverage production life cycle.

7. Scaling Up and Co-Packing

As demand grows, you may decide to scale up or outsource certain aspects of your beverage production:

1. Scaling Up In-House

• Upgrade to larger equipment to accommodate bigger batches.

• Adjust recipes and processes to maintain quality at higher volumes.

2. Co-Packing (Contract Manufacturing)

• Partner with a specialized facility that produces, packages, and sometimes even distributes your beverage.

• Ideal for reducing overhead costs and leveraging expert knowledge in beverage production.

3. Supply Chain and Distribution

• Develop relationships with distributors and retailers to expand market reach.

• Implement inventory and logistics strategies to avoid shortages or overstock.

8. Marketing and Launch Strategies

A strong launch strategy can be the difference between a successful product and one that never gains traction:

1. Brand Identity

• Develop a cohesive visual identity (logo, color scheme, packaging design).

• Craft a compelling brand story that resonates with consumers.

2. Promotional Channels

• Leverage social media, influencer partnerships, and traditional advertising.

• Offer tastings or samples in retail stores or at trade shows.

3. Feedback and Iteration

• Gather consumer feedback to refine flavor, packaging, or positioning.

• Stay agile and adapt based on evolving market trends.

9. Common Pitfalls and How to Avoid Them

1. Underestimating Costs

• Beverage production can be expensive, especially when scaling. Create a detailed budget for equipment, ingredients, and marketing.

2. Skipping Quality Control

• Inconsistent flavor or safety issues can damage your brand. Allocate resources to rigorous QC processes.

3. Ignoring Consumer Trends

• Failing to adapt to changing consumer preferences (e.g., reduced sugar, plant-based options) can leave you behind.

4. Poor Planning

• Rushing to market without thorough R&D and testing often leads to costly product recalls or rebranding efforts.

10. Final Thoughts

Embarking on a beverage production journey involves creativity, meticulous planning, and ongoing refinement. By understanding the entire lifecycle—from concept and formulation to packaging and marketing—you’ll set a solid foundation for creating beverages that stand out in a competitive market. Focus on quality, stay abreast of consumer trends, and never stop innovating. With the right approach, your beverage brand can achieve long-term success and delight customers around the world.

Key Takeaways

• Research and Conceptualize: Understand your target market, identify trends, and define your USP.

• Formulate and Test: Work on a solid recipe, test for flavor consistency, and ensure shelf stability.

• Quality and Compliance: Implement rigorous QC measures and follow all regulatory guidelines.

• Scale and Market: Efficiently scale production, explore co-packing options, and promote your brand effectively.

With these principles in mind, you’re now equipped to navigate the exciting realm of beverage production and bring your unique drinks to life. Good luck on your journey!

Beverage manufacturing Partners