We produce private label beverages in any size can or bottle, carbonated, non-carbonated, alcoholic & non-alcoholic.

We will get you from start to store in less than 90 days

We offer formulation, production and marketing services.

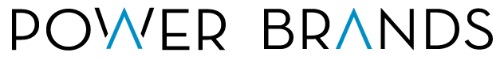

Trusted by Global Brands & Entrepreneurs

Talk to a private label beverage expert now

Private Label Beverage Services for Canned and Bottled Products

Our private label beverage service is designed to cater to global brands and startups, offering unparalleled flexibility and expertise. Whether you’re a corporation seeking high-volume production or a startup looking to pilot your next big idea, we have you covered.

Key Features of Our Service:

Custom Production Options: We produce beverages in a variety of formats tailored to meet your specific needs.

- Flexible Volumes: From small-batch pilot runs to large-scale global production, we adapt to your business stage and goals.

- Versatile Filling Capabilities: Hot-fill, cold-fill, carbonated, and non-carbonated processes are all available.

- End-to-End Support: We offer formulation, ingredient sourcing, design, and compliance to ensure your product is market-ready.

- Global Scalability: With state-of-the-art facilities and a streamlined supply chain, we support brands across international markets.

- Startup-Friendly Services: For new brands, we offer pilot production runs, testing capabilities, and guidance on scaling efficiently.

Whether you’re launching a new product or expanding your portfolio, our commitment to quality, innovation, and customer satisfaction ensures your success. Let’s bring your private label beverage vision to life, no matter the scale!

Before you set up your first mass production run, let us help ensure that your beverage formulation is ready for manufacturing. Request Free Information >

We will help you to purchase the raw materials for your beverage production.

We make sure the correct quantity of ingredients and any other raw materials are shipped to the point of production on time.

And, your beverage containers, caps, labels and cartons are the correct specifications & arrive ready to be turned into your drink.

Power Brands will help you ship and store your new beverage after production.

Our beverage production and logistics experts will guide you through quality control, shipping and warehousing your newly produced beverages. Working with a Power Brands beverage production expert will ensure that you have a less stressful and more successful experience. Request Free Information >

Comprehensive Guidelines for New Beverage Producers

Below is a detailed, step-by-step overview to help you navigate your first beverage production run. Each heading covers an essential step or consideration, with useful tips and information to set you up for success.

1. Double-Check All Label Details

Spelling & Graphics: Carefully review any text, images, or brand elements for errors or inconsistencies.

Nutritional & Supplement Facts: Have at least three people (who did not develop the product) check your panel and ingredient list. Ideally, involve experts from two different companies.

Importance: Correcting errors at this stage saves costly fixes later.

Request Free Information >

2. Have an FDA Label Attorney Review Your Label

Regulatory Compliance: An FDA Label Attorney ensures your labels meet federal requirements.

Protect Your Brand: Prevent costly recalls, fines, or legal complications get professional approval before going to market.

3. Obtain a Process Authority Letter for Each Variety

Purpose: This letter details how to safely process each flavor or variety of your beverage.

Importance: Each drink may have unique requirements for temperature, acidity, or other factors. Following these protocols ensures consumer safety.

Request Free Information >

4. Get Product Liability Insurance

Coverage: Secure insurance before your first production day.

Why It Matters: You’ll be protected once the product leaves your facility, mitigating financial risks if issues arise.

5. Verify Your Formula

Ingredient Transparency: Make sure all ingredients are recognizable and used at the correct levels.

Accuracy: Confirm the formulation is exactly what you want before large-scale production begins.

Request Free Information >

6. Use Established Suppliers

Longevity & Reliability: Prefer vendors who have been in business for 10+ years.

Quality Assurance: Larger, reputable companies typically offer more consistent product quality and dependable service.

7. Confirm Packaging & Equipment Compatibility

Test Runs: Verify your bottles, cans, caps, labels, and cases can be handled by the manufacturer’s equipment.

Avoid Surprises: An incompatibility can halt production, leading to costly delays.

Request Free Information >

8. Understand Lead Times & Minimum Orders

Schedule Smart: Base your production timeline on the longest lead item (e.g., specialty packaging).

Built-In Buffer: Allow an extra week (or more) before production to accommodate unexpected delays.

9. Expect & Plan for Delays

Realistic Timeline: First productions are learning experiences; raw material delays or equipment failures can happen.

Event Planning: Avoid scheduling major promotions or launches until you have a confirmed production date.

Request Free Information >

10. Provide Fresh Reference Samples to the Manufacturer

Consistency Check: Request samples from the lab where your drink was developed and send them to the manufacturer.

Comparison Testing: Use these fresh samples to compare flavor, color, and aroma just before filling to ensure accuracy.

11. Attend Your First Production Run

Hands-On Oversight: You know your drink best; be present to confirm taste, appearance, and quality.

Final Verification: Catch potential issues in real time and make on-the-spot adjustments if needed.

Request Free Information >

Useful Tip: Managing Costs & Materials

First Production Costs: Expect higher per-unit costs for initial runs - smaller volumes = less efficient economies of scale.

Price Setting: Request pricing for 250,000–1,000,000 units of each flavor to guide your budget. Aim for a minimum 50% profit margin (e.g., if production costs $0.50, sell to distributors for at least $1.00).

Raw Material Coordination: Ensure your bottles, labels, closures, and all ingredients arrive together. Missing even one component can halt the entire production. We can help you manage this efficiently.